Green Economy: Caterpillar Alternative Business Model

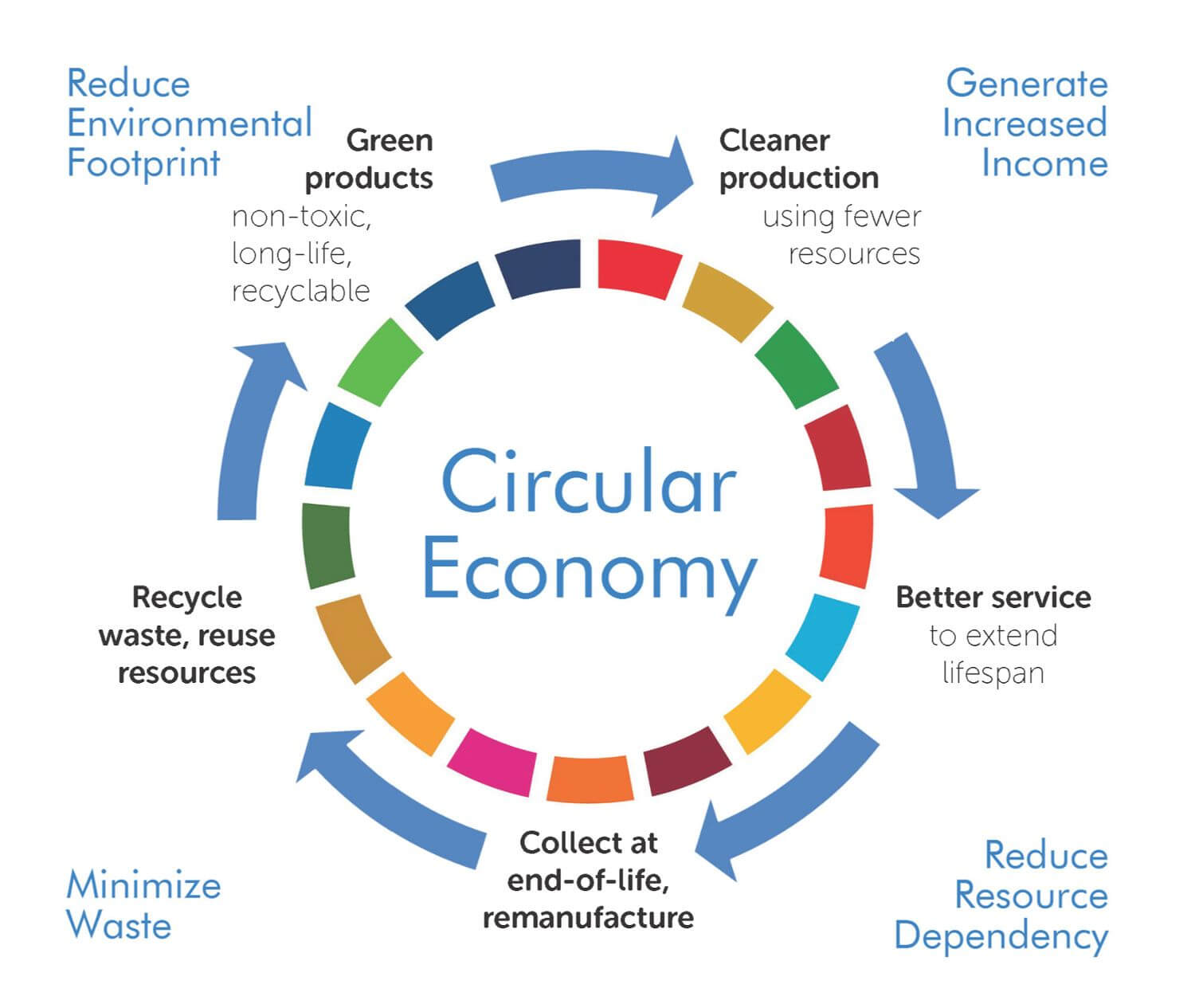

Green Economics is about doing business in new ways and changing business models to meet market demands of the emerging global circular economy. The following UN Case Study: Product Lifetime Extension: Caterpillar, how Caterpillar’s business model of re-manufacturing highlights the benefits to their customers, for its business and the environment. Also how the remanufacturing process can provide solutions that contribute to more sustainable production and consumption models.

This case study presents a successful business strategy to extend products lifetime. The aim with of this case study is to inspire and encourage organizations to shift to more circular models, to improve their business models towards prolonging or extending a product’s lifetime.

Context

Caterpillar is one of the world’s remanufacturing leaders, a strategy that focuses on extending a product’s lifetime to its maximum capacity and, consequently, use its resources in a more effective way.

Sector of activity: Solar Turbines and Progress Rail Services remanufacturing. Implementation area: Global operations in 110 facilities (51 plants in the USA and 59 plants in other 22 countries, headquartered in Illinois, USA)

Caterpillar’s remanufacturing is an exchange model, which means that when a component needs to be replaced, consumers works with their authorized ‘Cat Dealer’ to exchange their nonfunctional item and replace it by a remanufactured one. The ‘old’ product is then sent back to Caterpillar for remanufacturing. The remanufactured product typically costs less than half of a new one but has the same performance.

This represents an economic benefit to the consumer, since a remanufactured item is priced lower than a new one, and decreases the use of raw materials, through additive manufacturing techniques and reuse. A remanufactured product is not the same as a recycled or repaired product, since the complete component undergoes a process that replaces worn or unsalvageable parts with new parts and remanufactures others so that the component meets original manufacturers’ specifications. When a product is remanufactured, the parts that need replacement are submitted to an industrial process that returns the components to same-as-new conditions, or they are replaced with new parts.

Design is an important aspect of the remanufacturing business model, since products need to be durable, so that they can withstand as many lifecycles as possible – according to Caterpillar, some products can be repaired and re-manufactured for multiple lifecycles.

History

Over 45 years ago, Caterpillar was approached by a large customer of engines for on highway trucks that needed a repair option that was more time and cost effective than replacing their diesel engines with new ones. In the search for a solution to solve a customer request, Caterpillar saw an opportunity for business in remanufacturing, which was not widely known around the world and could be profitable for the company because it was innovative and attractive to consumers in financial and practical ways. The company then started looking for alternative engine overhauls that could turn the usual long repair method – taking days to be completed – to a process that shortened the time and complexity for servicing these engines.

Barriers

Once the new business model was implemented in Caterpillar’s first plant, they expanded this kind of work around the globe as companies started requesting it. Developed countries were the first ones to demand it and had a positive acceptance of remanufactured goods.

Some developing countries have been more resistant. According to Caterpillar, there are concerns to not be a “dumping ground for the developed world’s used goods”, which is also connected to a mis-conception of perceiving remanufactured products as old used products. This reasoning is not unjustified. In some countries that used to receive parts from other countries’ end-of-life products, for example, both society and government are now opposing this. Caterpillar is trying to reverse this image, and encourages the notion that the remanufacturing process is very different to discarding used, old or broken products in other countries.

Despite these challenges in developing countries, Caterpillar invested in a new unit in Brazil, choosing the city of Piracicaba, in the State of São Paulo, to build its first remanufacturing plant in South America. With this investment, Caterpillar is looking to show Latin American consumers and policy makers that remanufactured products are similar to new ones, but with less associated environmental and monetary costs. Just to illustrate this, Caterpillar highlights that the remanufacturing resulted in 134 million lbs of material remanufactured or recycled per year, the preservation of 85% of original energy “value add” and approaching the “zero landfill” status.

Having a regulation assisting the implementation of a new business model is a decisive factor for its approval in a country. Each country has its own legislation, and in the United States, for example, there are almost no barriers for the exchange market in NAFTA (North American Free Trade Agreement) regulations, which can help explain why remanufacturing is more popular in the country, both for government and consumers. This happens in many developed countries, where legislation on the matter is usually new or has been recently updated to recognize remanufactured products.

On the other side, many developing countries still have legislation mostly from the 1960s, in force which only recognizes new and used products. Caterpillar is also focusing on legislation that clarifies the value of remanufacturing and the remanufacturing market. The company is working with policy makers to develop and implement regulations that make the commercialization of remanufactured goods possible and accepted in those places.

Partnerships

Caterpillar sells its products through 180 independent dealers around the world. The company also works with the Remanufacturing Industries Council, an organization that communicates the benefits of remanufactured products in order to educate different stakeholders such as schools, academia, policy makers and consumers on this subject.

Other essential partnerships have been formed with organizations such as the Ministry of Industry and Information Technology (MIIT) of China and the Rochester Institute of Technology in New York that analyses Caterpillar’s reports in order to communicate the good results of the company’s work so that consumers can better understand the matter of this business.

Communication and results

On their website, Caterpillar explains – through videos, infographics and statements – how the remanufacturing exchange model works and its relation with the circular economy, emphasizing the environmental benefits of this business model and the positive results achieved through product lifetime extension.

Some of the benefits include a financial gain for consumers, such as clients and suppliers, due to lower operation costs for providing same-as-new performance, and more repair options. It also helps businesses reduce owning and operating costs.

How to get involved?

Everyone can contribute to a more sustainable industry sector. Consumers have a double role, both when deciding what to consume, looking for more durable products depending on their design and raw materials, but also when choosing products from companies that address key issues of the value chain, passing through raw material extraction and labor relationship, and that allow an adequate end-of-life management of the product, ideally extending its life or reinserting it into the chain.

This case study was compiled by Akatu Institute and UN Environment under the One Planet network Consumer Information Programme as follow up to the report The Long View, and funded by the French Ministry for Ecological and Solidary Transition.

UN Green Policy Platform June 2019

Source: One Planet Network

Leave a Reply

You must be logged in to post a comment.